This bottle sorting machine is the best assistant for high-speed production line; The precise and robust body design, with built-in storage space and bottle turntable, not only saves space, but also greatly reduces the noise generated by machine operation.

● Low-level detection sensor in the hopper for timely alerts.

● Siemens PLC control and a 7-inch color touchscreen can be set to either Chinese or English, providing a user-friendly interface for convenient operation.

● Over 50 sets of product parameter memory groups, allowing quick access to product production parameter data files.

● The exit end is equipped with a bottle backlog shutdown function. The machine will automatically start when the bottle accumulation condition is resolved.

● Equipped with movable casters for easy machine mobility.

● Can be installed in existing automated production lines.

● Stainless steel body and CE safety protective cover provide safety protection, preventing external dust pollution, and reducing machine operation noise.

● Specially designed for high specifications in pharmaceutical and nutritional food factories, in compliance with GMP standards.

Optional Accessories:

1.Extended exit conveyor belt.

2.Three-color warning light.

3.Hopper static elimination device.

4.Ion air blowing cleaning assembly.

5.Vacuum dust removal device.

Air blowing air filter quality

Capacity | Up to 200 bottles per minute (actual capacity depends on customer sample testing) |

Applicable Products | Round bottles, square bottles, rectangular bottles, oval bottles (not suitable for glass bottles) |

Applicable Size | Bottle diameter: Ø30-124 mm, Bottle neck inner diameter: Ø25 mm (same as bottle body), Bottle height: 45-220 mm, Bottle diameter/height ratio: Minimum 1:1.5 |

Hopper Capacity | 390 L |

Ion air blowing | 2 nozzles (optional) |

Voltage | 220 V, 50/60 HZ, 1 PH |

Air Pressure | 6 bar (87 psi) |

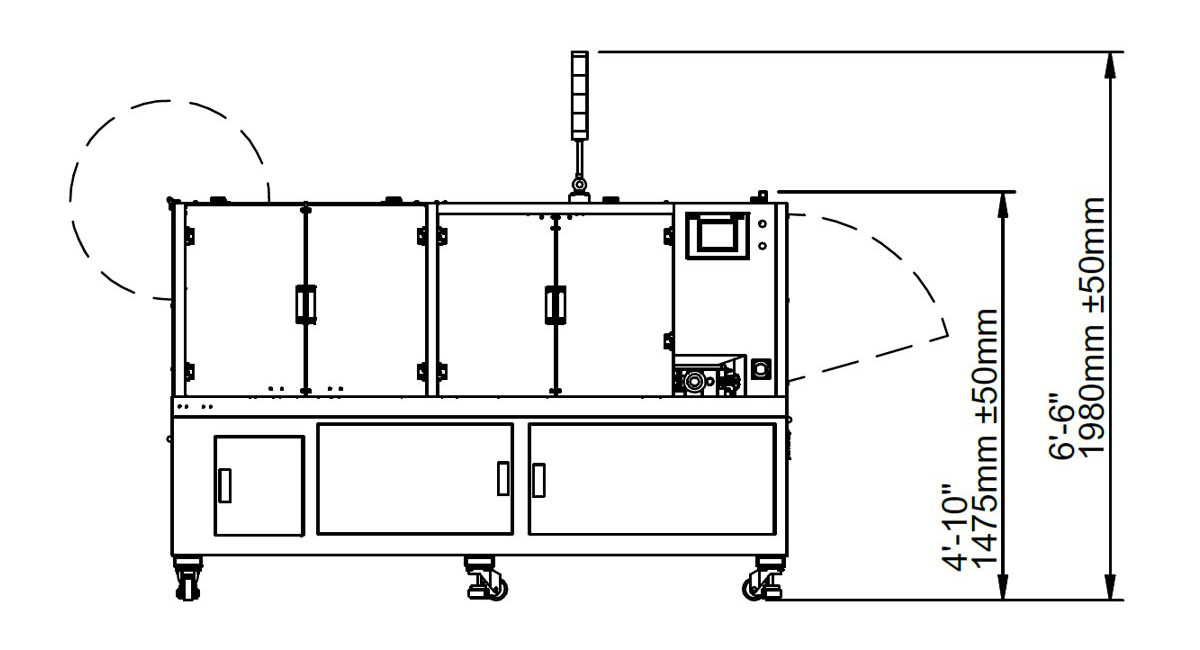

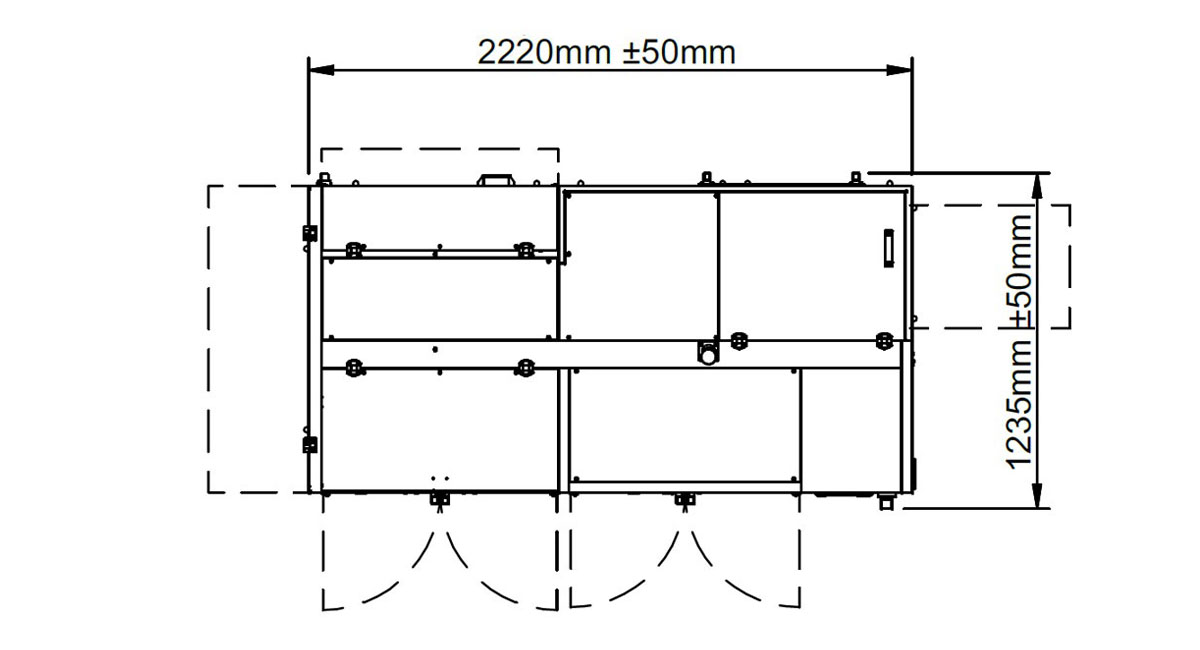

Machine Dimensions | 2,200 x 1,235 x 1,980 mm (Length x Width x Height) |

Machine Net Weight | 700 kg |