1. Liquid filling capping machine adopts two integrated design: linear translation liquid filling with rotary capping, high efficiency servo drive technology, to provide high-speed, stable and accurate liquid filling and capping.

2. During the liquid filling process, the screw connected by the main turret will transport the bottle to the filling station. During the liquid filling, the bottle can be followed while filling to achieve high-speed and stable liquid filling. The bottle filled with liquid will continue to enter the rotary capping station for capping operation. One machine can synchronously complete high-speed liquid filling and capping, greatly meeting customer capacity and space requirements.

● Precision servo-driven filling quantitative cylinder group.

● Mechanical linkage drives 4 capping heads.

● Submersible filling design: The filling nozzle submerges into the bottle and gradually moves upward, significantly reducing liquid foaming.

● Can be equipped with a submersible bottle or bottom-up filling nozzle based on liquid characteristics.

● Unique servo motor-driven control of the filling cylinder and filling nozzle ensures fast and high-precision filling.

● The main tower's mechanical linkage drives the screw for precise bottle conveying.

● Multi-stage adjustable filling and capping speed settings.

● Over 50 sets of product parameter memory groups for quick access and retrieval of product production parameter data.

● Bottle entry and exit equipped with photoelectric sensors for perfect monitoring of continuous production.

● The bottle mouth alignment group ensures that the filling nozzle aligns with the bottle mouth for submersible filling (requires R&D evaluation for customer products).

● Uses a 7-inch Siemens human-machine interface.

● Advanced servo motors for the rotation of the main tower; the lifting of the main tower uses a motor coupled with a gearbox.

● The lifting of the capping head uses a cam mechanism, suitable for various types of caps.

● Magnetic mechanism for precise control of the tightening torque of the capping head.

● The machine base, frame, panel outer shell, and materials in contact with the liquid are made of 304 stainless steel and 316L stainless steel.

Capping Heads | 4 |

Filling Heads | 8 |

Production Capacity | 100 bottles/minute (Data based on 100 ml round bottle testing) (Actual production capacity may vary based on customer sample testing.) |

Applicable Containers | Plastic bottles, glass bottles (For irregularly shaped bottles, please consult our technical team.) |

Filling Range | 5-60ml / 10-120ml / 50-500ml / 100-1000ml / 250-2500ml / 500-5000ml (Optional configurations) (Different specifications of filling cylinders need to be selected separately.) |

Applicable Liquid Viscosity | 2000 cps |

Voltage | 380V 50(60) HZ/ 3PH |

Power Consumption | 4600 VA (14 A) |

Air Pressure | 6 bar (87 psi) |

Air Consumption | 50 NLit/m (1.6 CFM) |

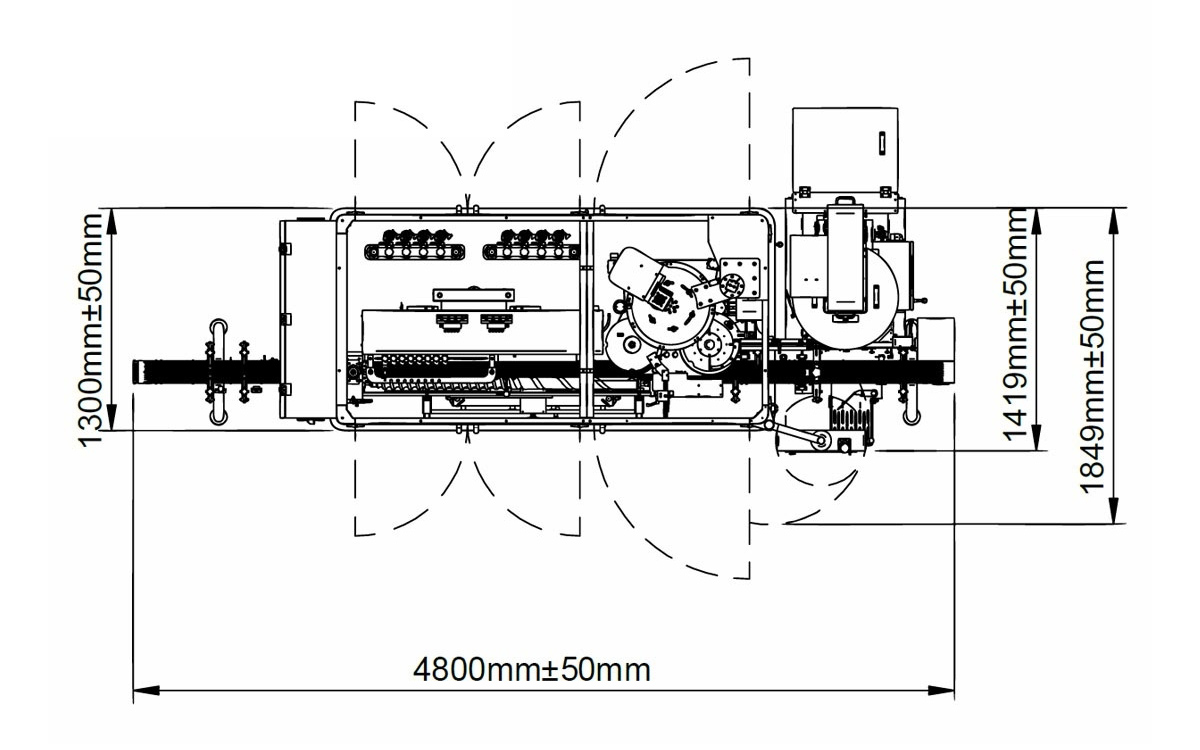

Machine Dimensions | 4,800 x 1,419 x 2,250 mm |

Machine Net Weight | 3450 kg |

Noise level | 80dB |

Filling Range and Accuracy | ±0.5- 1% |