This machine is suitable for quantitative filling of various non-aerated liquids, oils, and semi-fluids.

● This machine is suitable for quantitative filling of various non-aerated liquids, oils, and semi-fluids.

● It automatically completes a series of operations, including bottle counting, quantitative filling, and bottle conveyance. It is particularly suitable for quantitative filling of water-based solutions, emulsions, edible oils, fruit juices, medicinal liquids, etc. It is an ideal packaging equipment for industries such as food, pharmaceuticals, cosmetics, and fine chemicals.

● The linear (follow-type) translational liquid filling machine adopts advanced intelligent filling design with three-stage adjustable filling stroke, speed, and flow control. During filling, it synchronously conveys bottles in parallel to ensure stable, high-speed, and precise filling.

● Unique servo motor-driven control of the filling cylinder and filling nozzle ensures fast and high-precision filling.

● With over 50 sets of product parameter memory groups, it allows quick access to product production parameter data.

● Submersible filling design: The filling nozzle submerges into the bottle and gradually moves upward during filling, significantly reducing liquid foaming (can be matched with a submersible bottle or bottom-up filling nozzle according to liquid characteristics).

● Siemens PLC control system and Siemens color touch screen display production information and error messages, facilitating production management, maintenance, and troubleshooting.

● Servo control allows for multi-stage adjustable filling speed settings.

● For special-shaped bottles, such as oval bottles, specific servo-driven screw precise bottle positioning can be provided.

● Bottle entry and exit equipped with photoelectric sensors for perfect monitoring of continuous production.

● Stainless steel 304 machine base, frame, and outer shell panels, as well as materials in contact with the liquid, are made of stainless steel 316L.

Production Capacity | 96 bottles/minute (Data based on 250ml quantitative cylinder/120ml water and round bottle testing) (Actual production capacity may vary based on customer sample testing.) |

Applicable Containers | Applicable Containers: Plastic bottles, glass bottles (For irregularly shaped bottles, please consult our technical team.) |

Filling Range | 5-60ml/10-120ml/50-500ml/100-1000ml/250-2500ml/500-5000ml(Optional configurations) |

Applicable Liquid Viscosity | 2000 cps |

Voltage | 220 V/380V 50(60) HZ/ 1PH |

Power Consumption | 4600 VA (14 A) |

Air Pressure | 6 bar (87 psi) |

Air Consumption | 50 NLit/m (1.6 CFM) |

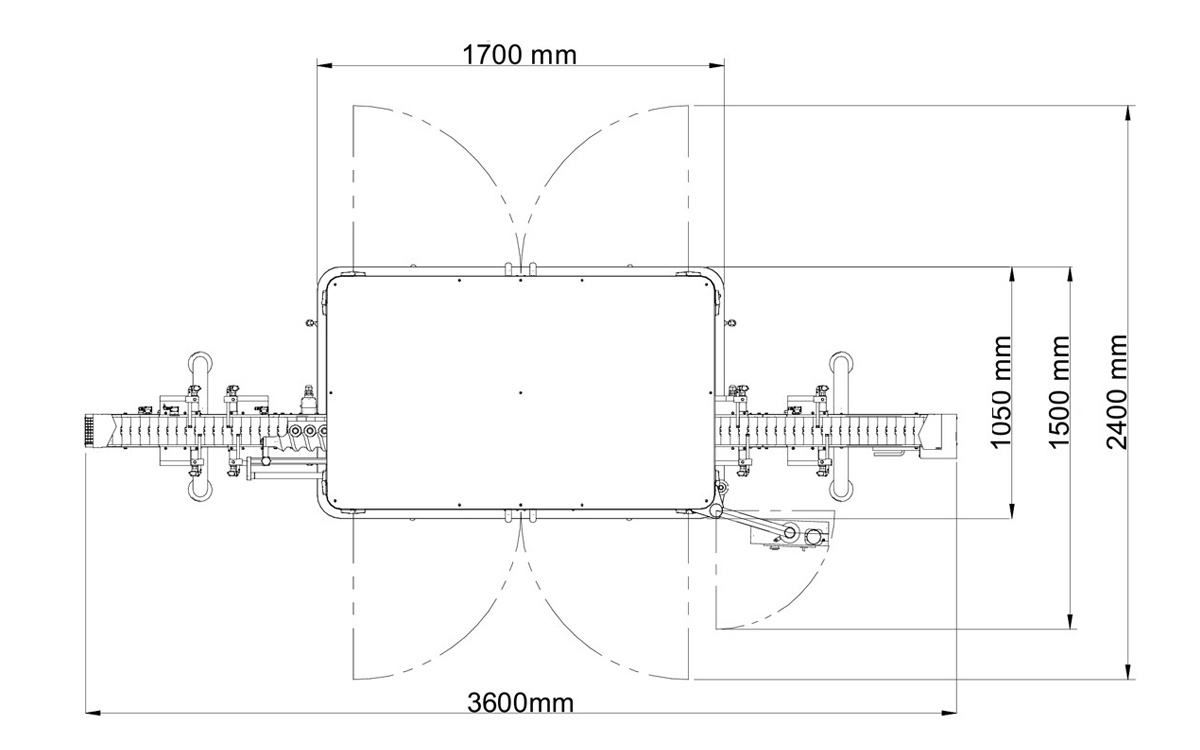

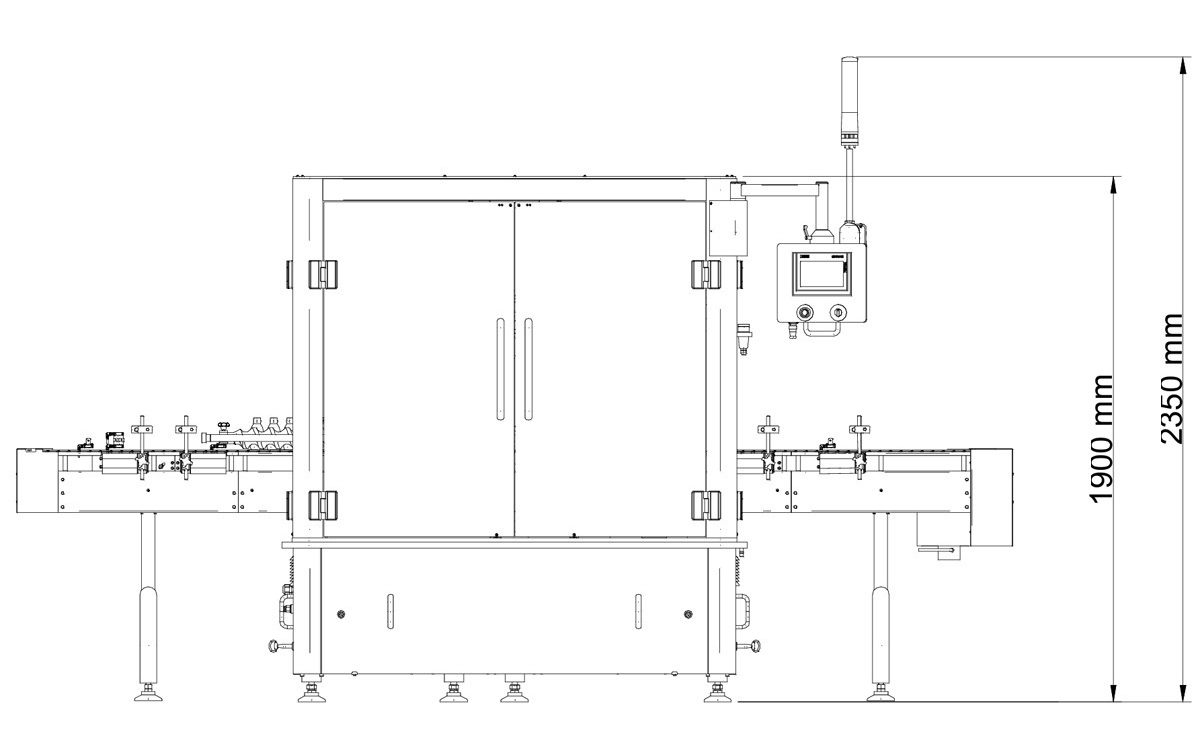

Machine dimensions | 3,600 mm x 1,050 mm x 2,350 mm |

Machine Net Weight | 1240 kg |

Noise Level | 70~75 dB |

Filling Range and Accuracy | ±0.5- 1% |