Specifically designed to meet the bottle packaging production line requirements of the pharmaceutical and health food industries.

Compact design with a built-in material storage space and bottle sorting turntable, saving space and significantly reducing machine operation noise.

Simple button-type operation.

● Uses air blowing design. If an inverted bottle is encountered, it is blown back to the star disk assembly for re-bottle sorting and orientation.

● Precise and easy-to-operate bottle sorting mechanism ensures that the bottle mouth at the exit is facing upward.

● Contact material with empty bottles is made of stainless steel 304.

● Stainless steel body with a transparent protective cover effectively isolates external dust pollution while providing comprehensive safety protection.

● Equipped with Siemens PLC system and a 7-inch touchscreen.

● Main machine structure made of stainless steel 304 and aluminum alloy, with FDA-approved materials, and fixed casters.

● Complies with GMP standards.

Optional Accessories:

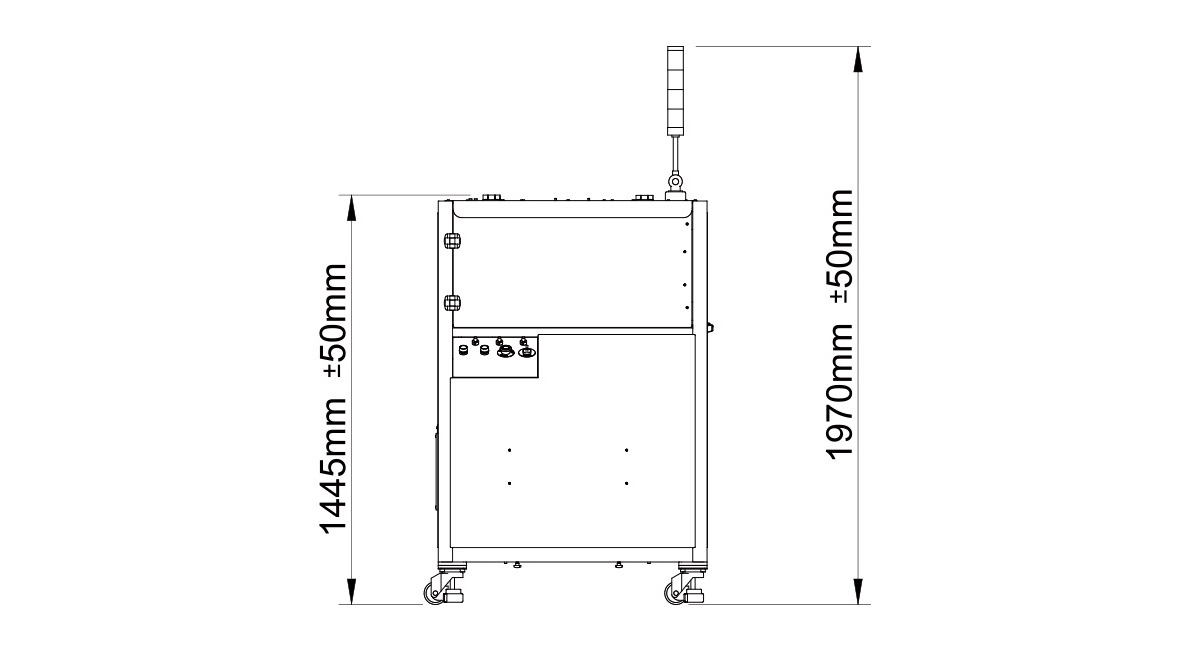

1.Tri-color warning light.

2.Bottle replacement kit.

Capacity | Up to 60-80 bottles per minute (actual capacity depends on customer sample testing) |

Applicable Products | Round bottles, square bottles, rectangular bottles, oval bottles (not suitable for glass bottles) |

Applicable Size | Bottle diameter: Ø30-80 mm, Bottle height: 50-150 mm, Bottle diameter/height ratio: Minimum 1:1.5 |

Hopper Capacity | 227 L |

Voltage | 220 V, 50/60 HZ, 1 PH |

Air Pressure | 6 bar |

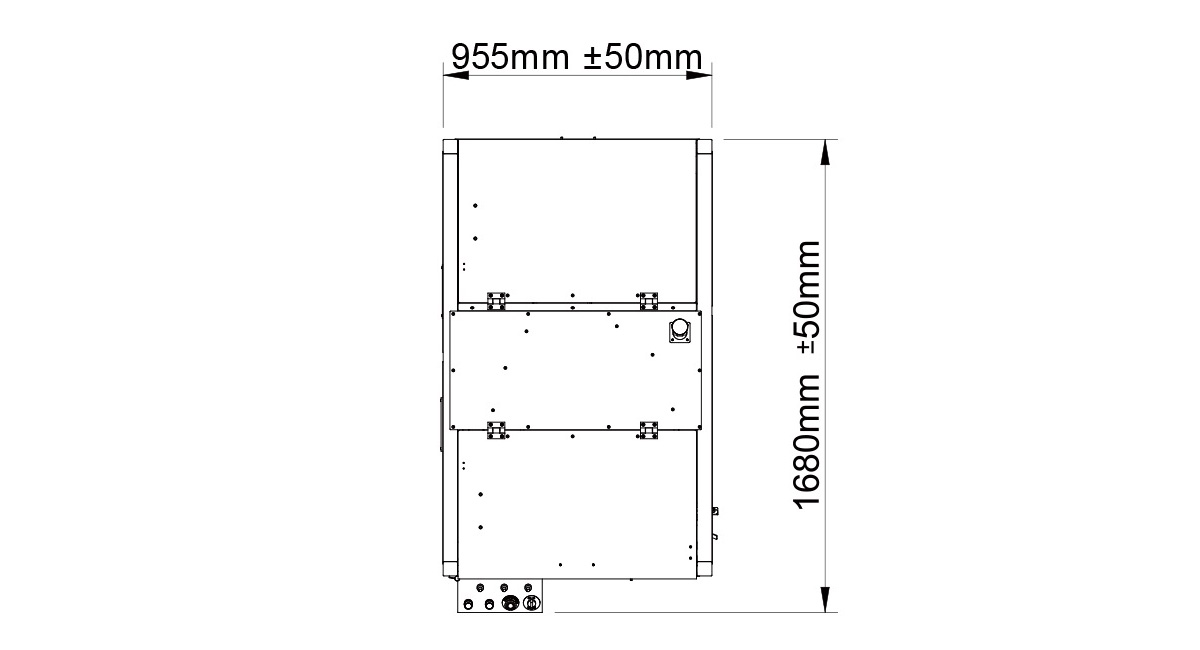

Machine Dimensions | 955 x 1,680 x 1,970 mm (Length x Width x Height) |

Machine Net Weight | 300 kg |