This machine is suitable for industries such as pharmaceuticals, food, cosmetics, chemicals, and medicines.

● This machine is suitable for industries such as pharmaceuticals, food, cosmetics, chemicals, and medicines. It features a high level of automation and a wide range of applications.

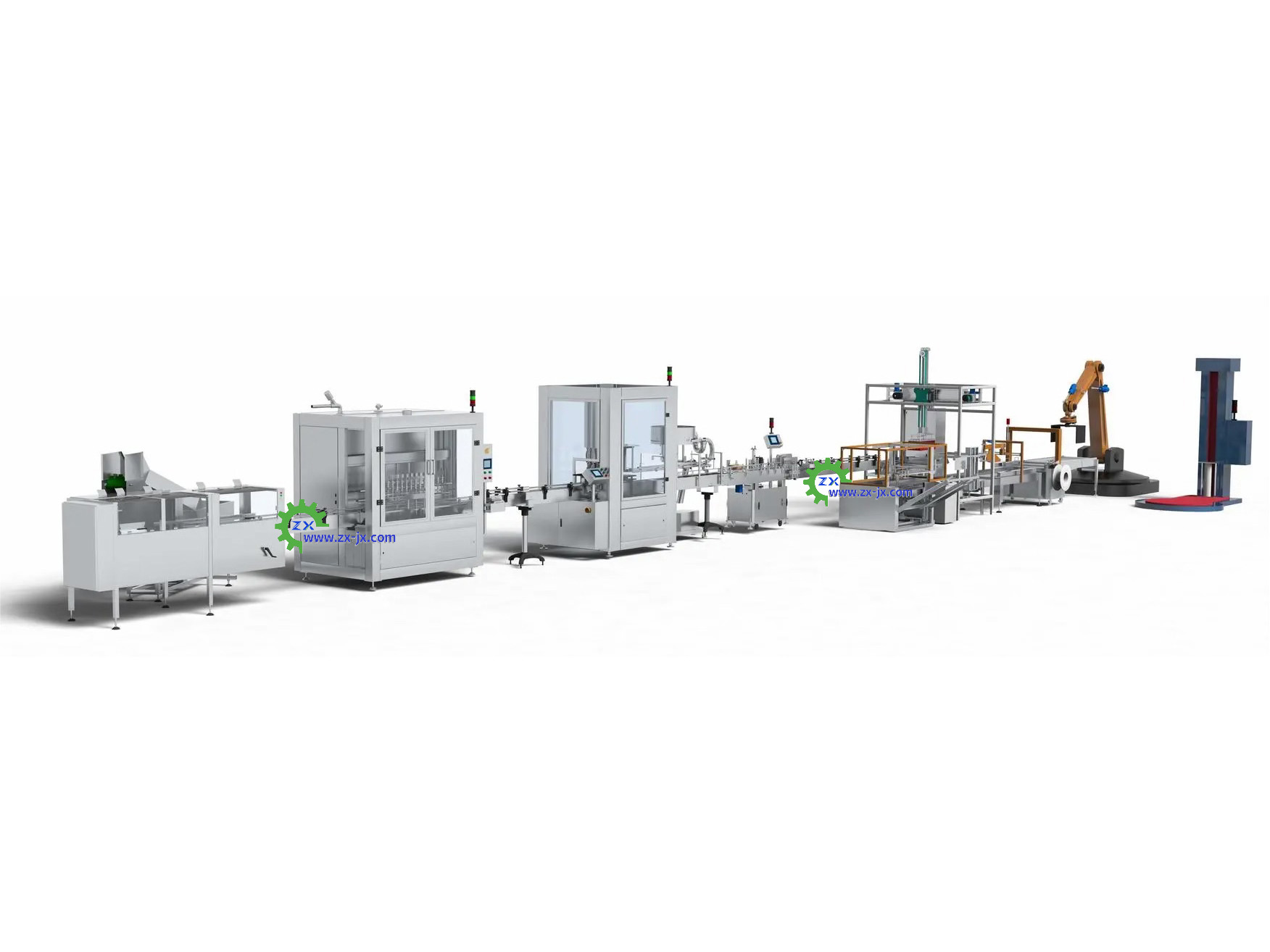

● Bottle Sorting Machine: After pouring the bottles into the bottle sorting hopper, the machine automatically arranges the bottles in a uniform direction and conveys them to the filling machine.

● Filling Machine: Controlled by a servo motor, the filling nozzles are inserted into the bottles from the bottom to fill them from bottom to top. This increases filling speed while significantly reducing material foaming and splashing. It is suitable for filling different specifications and types of liquids and pastes. The parts in contact with the material are made of 316L stainless steel, and the chassis is made of stainless steel 304, complying with GMP standards.

● High-Speed Capping Machine: Achieves functions such as automatic cap feeding, automatic cap grabbing, and automatic servo capping.

● Labeling Machine: Can meet the labeling requirements of various specifications and forms of self-adhesive labels (single-sided, double-sided, round bottle, flat surface, double-sided, etc.).

● Automatic box opening, packing, sealing, strapping, palletizing, etc., realize the automation of backend packaging, saving labor costs.

Process Flow:

Automatic bottle sorting - Servo filling - Automatic capping - Automatic servo capping - Automatic labeling - Automatic box opening - Automatic packing - Automatic sealing - Automatic strapping - Palletizing - Wrapping with cling film

Filling Range | 10-60ml/50-500ml/100-1000ml/500-5000ml(optional) |

Capacity | 80-100 bottles/minute (depending on factors such as filling capacity and bottle mouth size) |

Voltage | 380V 3P 50/60HZ |

Power | Approximately 10.5KW |